Takamisawa Cybernetics recognize that global environment conservation is one of the most important and urgent issues in the world. We obtained approval in the form of the ISO-14001 (internationally recognized environmental management) certification on April 18, 2003 to fulfill our social responsibility. We will continue our activities for global environment conservation from here on out.

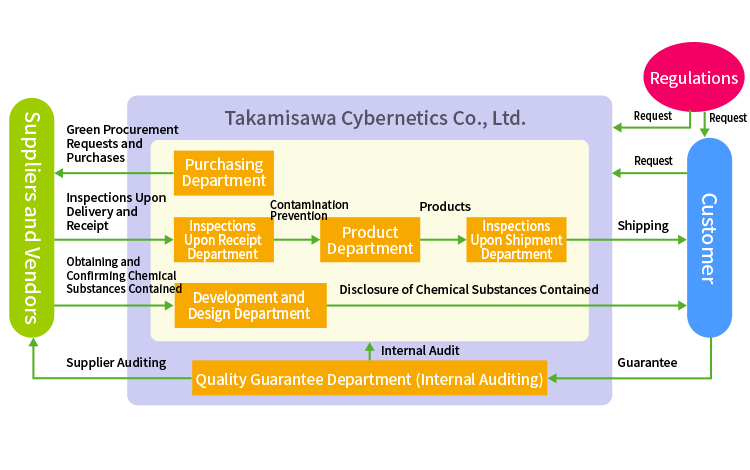

Especially at present, we have developed environmentally-friendly products in line with the most important issues of global environment conservation. At the same time, we are developing a management system for chemical substances in products which prevents products from including regulated chemical substances at the procurement stage to shipment, and for ensuring the reliability of information of chemical substances used and contained in our products.

Green procurement

Procuring parts and materials that do not include regulated chemical substances from upstream suppliers and sources is indispensable to managing green procurement products so that they do not include said substances. Therefore, we enacted a “Green Procurement Protocol” in September 2007, published it on our website, and made sure our supplier and source companies were apprised of it. In this protocol, we establish chemical substances for which inclusion in parts and materials delivered to our company is forbidden, and require all our supplier and source companies to provide us with information concerning chemical substances included in the goods they provide us.

Procuring parts and materials that do not include regulated chemical substances from upstream suppliers and sources is indispensable to managing green procurement products so that they do not include said substances. Therefore, we enacted a “Green Procurement Protocol” in September 2007, published it on our website, and made sure our supplier and source companies were apprised of it. In this protocol, we establish chemical substances for which inclusion in parts and materials delivered to our company is forbidden, and require all our supplier and source companies to provide us with information concerning chemical substances included in the goods they provide us.

Inspections upon receipt

We are working to use the results of checks of the information concerning chemical substances included in parts and materials provided to use by each of our source and supplier companies as a basis for procuring parts and materials that do not include chemical substances forbidden by our company. However, as there is a chance that human error or technical factors could result in the unintentional inclusion of regulated chemical substances, we set aside parts and materials for which there is a high risk of inclusion of said substances, and measure the amounts of specific chemical substances (substances regulated under the RoHS directive) contained in these goods by means of X-ray fluorescence spectrometers.

Production

Product evaluation

“Product environmental assessment” is a method for pre-evaluating products during the development stage for environmental-friendliness. We established criteria and procedures for evaluating products during the development of new products. Our viewpoint prioritizes environmental preservation initiatives such as conserving resources and energy economizing, and because of this we have bolstered checks of chemical substances included in products, and require that new products complete product evaluation as a condition for greenlighting for production and sales.

Preventing misuse, adulteration, and contamination

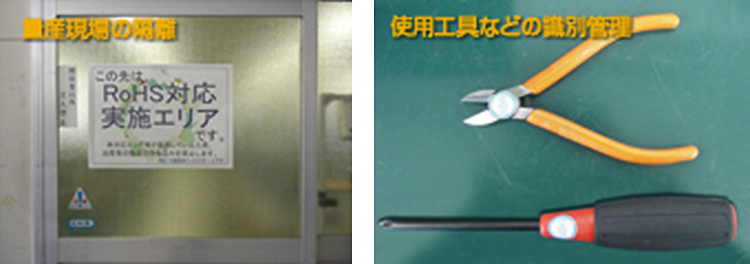

We deliver our products to customers not only in the electrical/electronic devices to which the RoHS directive is applicable but also a diverse array of other industries. Therefore, our customers can be divided into those who want RoHS directive-compliant products (*2 = example: products that use lead-free solder), and those who want products that are not (example: products that use lead-based solder) for purposes such as ensuring high reliability. Because of this, we take pains to prevent misuse, adulteration, or contamination so that RoHS directive-compliant products (*2) are not contaminated with unexpected chemical substances (such as substances regulated under the RoHS directive) that are prohibited from use and should not adulterate (must not be included or used in) the original product during mass production such as in the receipt/manufacture/shipping process or in storage spaces, warehouses, etc. Means for preventing this include identity management, keeping the products separated, and establishing procedures and standards.

Delivery

Preventing shipment of the wrong products

We register all products as either compliant or noncompliant with the RoHS directive to our production system (our core in-house system) in order to prevent mistaken shipping of noncompliant products due to human error. This allows for identification management that distinguishes between RoHS directive compliant and noncompliant products starting from the procurement stage, to provide customers with highly-reliable products thanks to our thoroughgoing implementation of said identification management in inspection upon receipt and prevention of misuse, adulteration, and contamination.